Orchestrate demand and supply planning for better predictability

Leverage consumption insights for increased profitability

Supply chain planning in consumption-driven categories can be complex. The ability to accurately sense demand on time becomes a critical driver for revenue growth for food brands. We have coded our comprehensive knowledge of the industry into a proprietary methodology to forecast and fulfill demand while assisting businesses in capitalizing on every revenue opportunity to grow profitably. Accurate demand projections improve supply planner visibility and transparency. Supply chains work smoothly when demand planning coordinates with all business processes, positively impacting business revenues.

Understand why focusing on consumer trends is the need for modern supply chains

Outcome driven demand planning for precise predictability

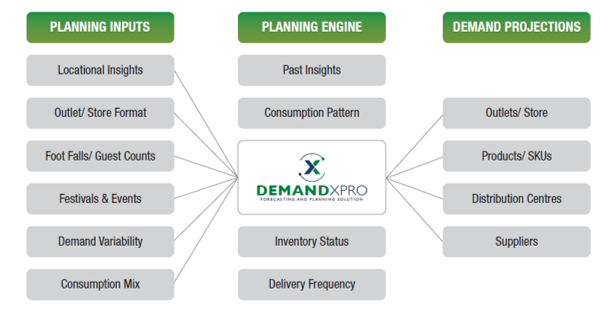

Demand planning greatly affects supply planning systems by projecting future demand trends, allowing planners to better adapt to changing consumer needs. DemandXPro is our intelligent proprietary tool for forecasting demand accurately across channels and product categories, particularly in the context of the Indian food service industry. The system uses machine learning algorithms to forecast future demand and give actionable insights based on transactional and semi-structured micro and macro data such as seasonality, festivals, promotions, growth trends, and changing culinary preferences. Combinations of Statistical and Machine Learning Methods specific to India’s food consumption patterns are deployed to arrive at the best possible solution for the most complex problems in the supply chain. These help with:

- Increased forecast accuracy

- Reduced loss of sale

- Near-zero expiries

- Consolidated actionable insights

Improve supplier performance through effective planning solution

Measuring, analyzing, managing, optimizing, and tracking supplier performance is critical to achieving predicted savings. Our Supplier Management System is an integrated solution that enables detecting, tracking, and assessing supplier lifecycle risk, correcting systemic risks, and managing supplier interactions. This is achieved through streamlining logistics procedures to increase efficiency and reduce delivery costs. The system also enables Material Requirement Planning to ensure that suppliers receive the correct purchase orders on time along with visibility on demand forecasts and safety stocks thus reducing stockouts and payment delays. Supplier scorecards record quantitative and qualitative performance data giving you better control over supplier data.

Outsource your procurement to unlock greater efficiencies in your P2P cycle

Regulate cash flow through effective inventory planning

Our inventory planning methodology promotes a smooth supply chain by allowing businesses to keep a close track of their inventory thus avoiding overstocking or outages by knowing what they have in stock, where it is, and when it needs to be refilled. With our decades of experience in the food ecosystem and understanding of inventory patterns, we help firms better adapt to food industry fluctuations and anticipate changing trends. Our integration of demand and supply indicators can help develop effective inventory planning. Monitoring inventory movement provides a greater awareness of market circumstances, hazards, and delays, allowing for more flexible planning. Good inventory management prevents other overstocking issues like product expiries and wastages, helps respond to market changes quickly and reduce costs.

Manage inventories efficiently with our agile warehousing solutions

Planning solutions tailored for success

- End-to-end Demand Planning

- Demand Planning Strategy

- Demand Planning System Design

- Product Life-cycle Design

- Demand Planning Management & Operations

- Advanced Insights and Analytics

- Material Requirement Planning

- Capacity Planning

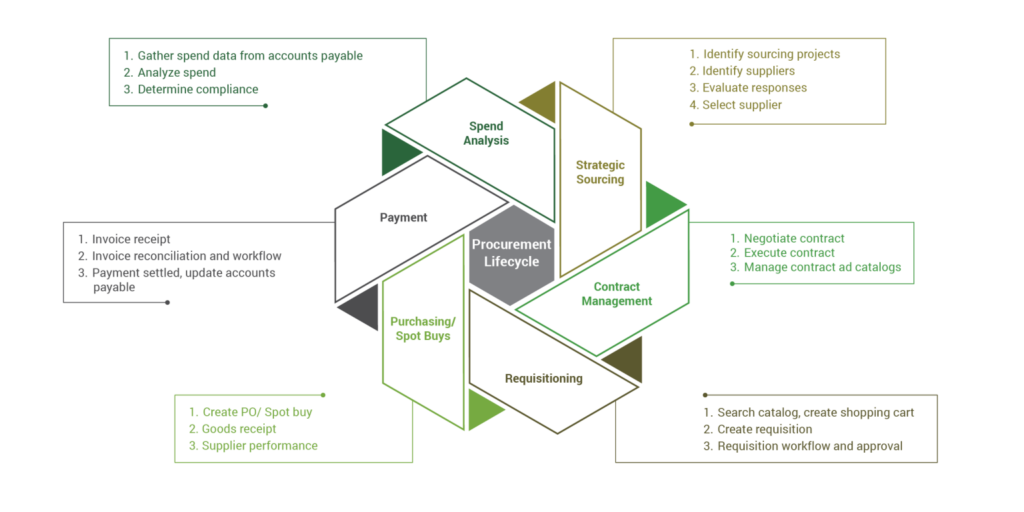

- Procure to Pay Cycle Management

- Supplier Performance Management

- Integrated Planning

- Inventory Rationalization

Together we can achieve these outcomes

Improve supply chain visibility

Optimised Inventories

Increased profitability

Improved order fulfilment

Improved production scheduling

Increase cash flow

Connect with your experts to re-imagine your supply

chain planning strategy

Resources

Strategically Built DC’s with a Holistic Project Management Approach

Situation A leading Retail Chain in South India in the Food & near Food categories wanted to build two Distribution...

Read MoreFocusing on Consumer Trends: Need for Modern Supply Chains

As a company’s business drivers change, business processes, SCM technology investment and the overall approach to supply chain management must...

Read MoreHow Packaging Influences Supply Chain Management

The role of packaging is important in supply chain operations as it impacts cube on trucks, inventory storage, product safety,...

Read More10 New Year Resolutions for Food Supply Chain Brands (Part 1)

With the advent of 2022, we are all gearing up for changes, as individuals and as organizations. Reformed environmental standards...

Read MoreFAQs (Frequently Asked Questions)

What are demand planning and forecasting?

Demand planning and forecasting is the process of planning, predicting or forecasting the demand of products in the market to assure inventory and stock management. It helps deliver the right products in the right quantities that satisfy the customer demand without resulting in excessive production or deficit supply.

Supply chain companies in India catering to logistics requirements help with systematic demand planning and forecasting. The process of preparing the demand planning and forecasting is as follows,

- Preparation of data based on past market demand and analytics

- Initial forecasting

- Using market intelligence to integrate the supply chain of demand forecast

- Analysing the data with different operational data of specific years and predictions

- Determine final data through demand planning and forecasting

- Monitor the data to make changes for further improvement

Why demand planning and forecasting is essential?

Demand planning and forecasting help determine all business decisions and streamline them in the most effective way possible. Since operating decisions are generally based on the product’s market demand, demand planning and forecasting beforehand help with arranging the supply chain and end-to-end integration. Promoting efficient supply chain integration, demand planning and forecasting also prepare the company for future uncertainties like lack of supply or excessive production compared to demand.

The 4 crucial elements of demand planning are

- Analysing demand based on the product type- Understanding the market’s demand and the types of goods demanded.

- Analysing demand based on the quantity requirement- Understanding the market demand to produce the quantity demanded.

- Analysing the demand and forecasting the time – Forecasting the time of demand concerning the product type, quantity, etc.

- Analysing the supply chain to meet the demand- Integrating the supply chain from end-to-end to help fulfil the demand whenever required.

What are the different methods used for demand planning and forecasting?

There is a number of methods used for Demand planning and forecasting, given the nature of business and products. To list a few among them, here are the top forecasting methods used for supply chain integration.

- Moving average forecasting

- Exponential smoothing

- Auto-regressive integrated moving average

- Bottom-up forecasting

- Quantitative and Qualitative forecasting